In today’s fast-evolving world of manufacturing, CNC (Computer Numerical Control) technology has become a cornerstone for precision, efficiency, and innovation. Whether you’re a beginner looking to understand CNC or someone exploring its applications, this guide will provide you with the essential knowledge to get started.

What is CNC?

CNC, or Computer Numerical Control, refers to the automated control of machining tools (like drills, lathes, and mills) by a computer. With CNC technology, manufacturers can produce precise, complex parts with minimal human intervention.

At its core, CNC relies on pre-programmed computer instructions (commonly in the form of G-code) to control the movement of tools and machinery. This level of automation ensures accuracy, repeatability, and efficiency in producing a wide range of products—from aerospace components to custom jewelry.

How Does CNC Work?

CNC machining involves a few fundamental steps:

- Designing the Part: The process begins with a digital blueprint created using CAD (Computer-Aided Design) software.

- Generating the Toolpath: The CAD file is converted into CAM (Computer-Aided Manufacturing) instructions, often in G-code, which dictate the tool’s movement, speed, and operations.

- Machine Setup: The raw material (e.g., metal, plastic, or wood) is loaded onto the CNC machine, and the required cutting tools are installed.

- Execution: The CNC machine follows the programmed instructions to cut, drill, mill, or shape the material into the desired part.

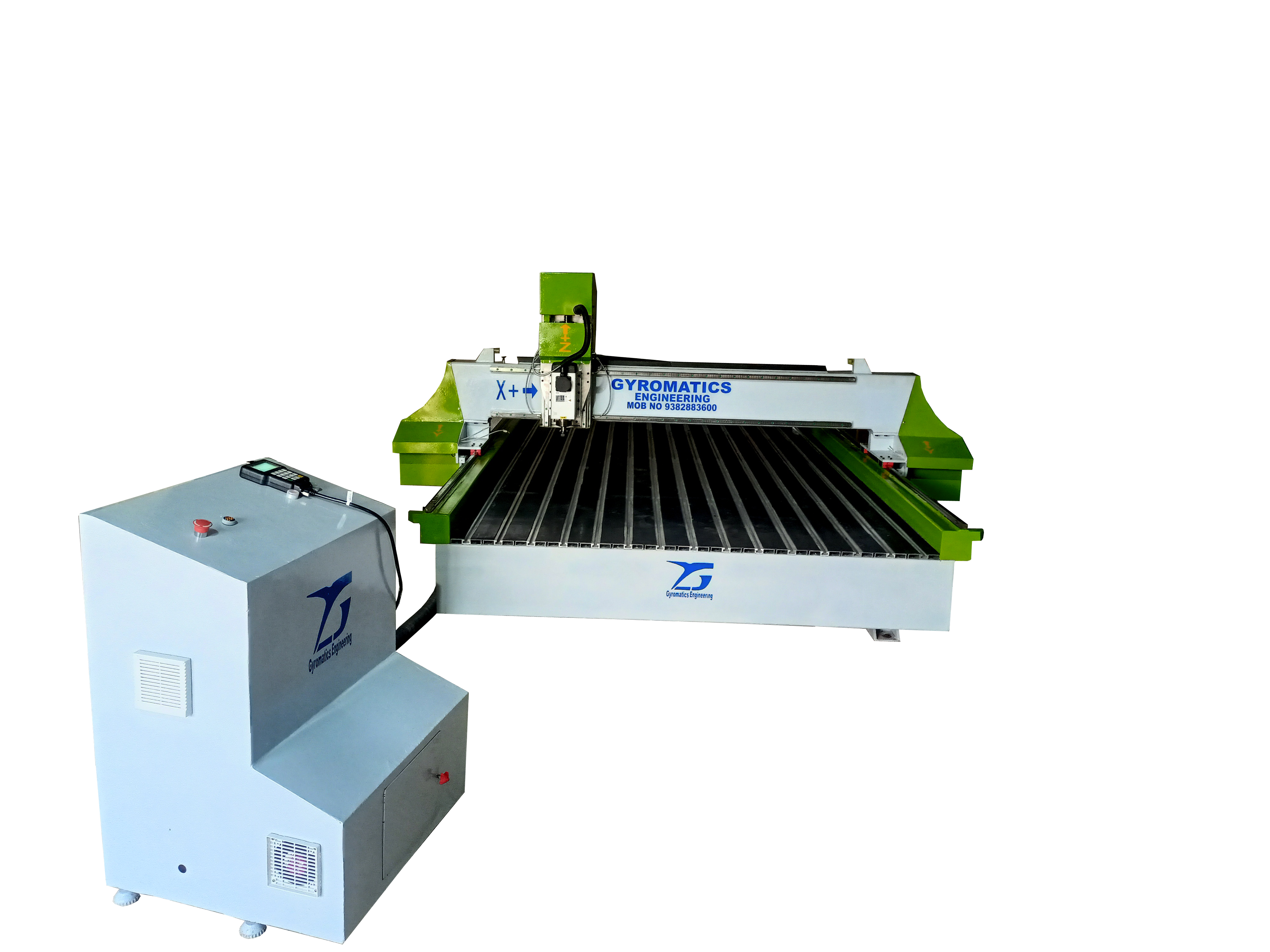

Types of CNC Machines

CNC technology is versatile, supporting various machine types, each tailored to specific tasks:

- CNC Milling Machines: Used for cutting and shaping materials along multiple axes.

- CNC Lathes: Ideal for cylindrical parts, rotating the material while cutting.

- CNC Routers: Commonly used for wood, plastics, and softer materials.

- CNC Plasma Cutters: Used for cutting metal with a plasma torch.

- CNC Laser Cutters: Provide precision cutting and engraving using lasers.

- 5-Axis CNC Machines: Offer advanced flexibility and capability to work on complex geometries.

Benefits of CNC Technology

CNC machines have revolutionized modern manufacturing with several advantages:

- High Precision: Ensures consistent accuracy, even for intricate designs.

- Increased Efficiency: Operates continuously with minimal downtime.

- Repeatability: Delivers identical parts, batch after batch.

- Versatility: Handles a wide range of materials and applications.

- Reduced Labor Costs: Requires less manual intervention compared to traditional methods.

Applications of CNC

CNC technology is used across various industries, including:

- Aerospace: Manufacturing precision-engineered components.

- Automotive: Producing gears, shafts, and custom parts.

- Healthcare: Creating surgical tools and prosthetics.

- Electronics: Fabricating circuit boards and enclosures.

- Art and Design: Crafting custom furniture and sculptures.

Challenges of CNC Machining

Despite its numerous advantages, CNC technology comes with challenges:

- High Initial Investment: CNC machines can be expensive to purchase and maintain.

- Skilled Programming: Requires trained professionals to program and operate effectively.

- Material Limitations: Some materials may be difficult or costly to machine.

The Future of CNC

CNC technology continues to evolve, integrating with innovations like:

- IoT (Internet of Things): Enabling real-time monitoring and smart manufacturing.

- AI and Machine Learning: Improving efficiency and predictive maintenance.

- Hybrid Manufacturing: Combining CNC with additive manufacturing (3D printing).

Conclusion

CNC technology has transformed manufacturing, offering unparalleled precision, efficiency, and versatility. As industries continue to embrace automation and digital transformation, CNC will remain a vital tool in shaping the future of production. Whether you’re an aspiring machinist, an engineer, or simply curious, understanding CNC is your first step toward unlocking its vast potential.

weed shipping usa secure packages

[url=byfurniture.ry]Дизайнерская мебель премиум класса[/url] — это воплощение изысканного стиля и безукоризненного качества.

Заключение о важности дизайнерской мебели нельзя игнорировать. Дизайнерская мебель не просто украшает пространство, но и наполняет его смыслом. Выбор в пользу дизайнерской мебели — это выбор в пользу долговечности и стиля.

Been playing at Manalobetcasino and I gotta say, I’m impressed. Good selection of games and the bonuses are pretty sweet. Time to win big on manalobetcasino.

Alright lads, finally checked out kubetkubet77. Interface is pretty decent, and the selection of games is not bad at all. Worth a look if you’re bored. Take a punt at kubetkubet77

Автосервис Тойота в Москве предлагает широкий спектр услуг. В этом автосервисе вы найдете опытных техников, которые знают все о Тойота.

Если вам нужен качественный и надежный [url=https://servis-toyota-moskva.ru/remont-toyota-v-moskve/] автосервис Toyota[/url], мы предлагаем широкий спектр услуг для вашего автомобиля.

Ремонт и обслуживание Тойота требуют от специалистов глубоких знаний. Все работники имеют соответствующую квалификацию и опыт.

Техническое оснащение сервиса соответствует самым высоким стандартам. Это позволяет проводить диагностику и ремонт на высшем уровне.

Наш автосервис обеспечивает надежность и долговечность вашего автомобиля. Наши клиенты всегда остаются довольны результатом работ.

В Москве существует множество автосервисов, специализирующихся на Тойота. В этом автосервисе вы найдете опытных техников, которые знают все о Тойота.

Если вам нужен качественный и надежный [url=https://servis-toyota-moskva.ru/remont-toyota-v-moskve/] автосервис Тойота в Москве[/url], мы предлагаем широкий спектр услуг для вашего автомобиля.

Для Тойота необходим высокий уровень квалификации. Каждый механик проходит специальное обучение и сертификацию.

В нашем сервисе используются современные технологии и оборудование. Благодаря этому, мы можем гарантировать качество выполняемых работ.

Наш автосервис обеспечивает надежность и долговечность вашего автомобиля. Наши клиенты всегда остаются довольны результатом работ.

Этот метод используется для улучшения поисковых позиций в выдаче.

[url=https://usileniessylok.ru/] Закупка ссылок:[/url]

Ссылки укрепляют авторитет и доверие к вашему веб-ресурсу.

Качественный контент способен вызвать заинтересованность и привести к ссылкам.

Необходимо иметь разнообразные источники ссылок для достижения успеха.

Как не попасться на мошенников в интернете [url=https://ne-popadis.org/]Как не попасться на мошенников в интернете[/url].

как не попасться на мошенников в интернете [url=https://ne-popadis.org/]https://ne-popadis.org/[/url]

франшиза дискаунтер ритейл [url=http://www.oneprice.shop]https://oneprice.shop/[/url]

http://zdspb.ru/goto/?link=http://oneprice.shop

Alright, so gachoic1 seems to be all about cockfighting. Not my cup of tea personally, but if you’re into that, it looks like this site covers it. Check it out if you dare: gachoic1

[url=https://title-balcony.site/]The Title Balcony layout[/url] is a modern beachfront condominium in Phuket, located on the coast in the Nai Yang area.

The Title Balcony Nai Yang emerges as a cutting-edge beachfront condominium in Phuket, placed directly along the coastline in the Nai Yang area. This condominium offers breathtaking views of the Andaman Sea provides stunning vistas of the Andaman Sea . The location is perfect for those who want to wake up to the sound of waves ideal for individuals who wish to awaken to the sound of waves . The Title Balcony Nai Yang is designed to offer a luxurious lifestyle constructed to present an opulent lifestyle.

Используйте [url=https://t.me/s/winelab_promokod]Промокод на скидку в винлаб[/url], чтобы получить выгодную скидку на первый заказ в приложении.

Необходимо активировать промокод своевременно, чтобы воспользоваться скидкой.

Если вы хотите повысить свои навыки продвижения, обязательно пройдите [url=https://t.me/s/seo_pro100]уроки XRumer и GSA[/url], чтобы эффективно использовать все возможности этих инструментов.

Опыт использования GSA ser помогает ускорить продвижение сайтов.

Благодаря тому, что [url=https://t.me/s/shectakova]ботулинотерапия[/url] является широко распространенным и эффективным методом в косметологии, многие люди могут добиться значительных улучшений в своем внешнем виде без необходимости хирургического вмешательства.

это современный метод борьбы с морщинами и другими признаками старения . Она включает в себя введение небольшого количества ботулинического токсина в определенные области лица, что способствует уменьшению видимости мелких морщин и обновлению кожи. Эта процедура получила широкое распространение в последние годы благодаря своей эффективности и безопасности .

Ботулинотерапия используется для коррекции формы бровей и придания лицу более молодого и свежего вида . Она может быть выполнена в течение короткого времени, обычно от 15 до 30 минут . После процедуры paciente может сразу же вернуться к своей обычной деятельности .

**Раздел 2: Преимущества ботулинотерапии**

Ботулинотерапия позволяет пациентам выглядеть моложе и свежее без необходимости хирургического вмешательства. Она получила широкое распространение благодаря своей способности уменьшить глубину морщин и складок . Ботулинотерапия также является относительно быстрой и безболезненной процедурой .

Ботулинотерапия применяется не только для косметических целей, но и для лечения различных медицинских состояний . Она может быть использована для улучшения качества жизни пациентов с определенными медицинскими состояниями . Ботулинотерапия должна выполняться только квалифицированными специалистами, чтобы обеспечить безопасность и эффективность процедуры .

**Раздел 3: Противопоказания и возможные осложнения**

Ботулинотерапия, как и любая медицинская процедура, имеет определенные противопоказания и возможные осложнения, которые необходимо учитывать . Противопоказания для ботулинотерапии должны быть тщательно оценены перед процедурой, чтобы обеспечить безопасность пациента.

Возможные осложнения ботулинотерапии могут включать временное онемение или слабость мышц . В редких случаях пациент должен быть тщательно проинформирован о возможных рисках и осложнениях перед процедурой. Ботулинотерапия требует тщательного подбора пациентов и планирования процедуры .

**Раздел 4: Заключение и перспективы**

Ботулинотерапия может быть использована для лечения широкого спектра состояний, от морщин и складок до гипергидроза и мигрени . Она является перспективным методом лечения в различных областях медицины.

Ботулинотерапия должна быть выполнена в соответствии с современными медицинскими стандартами и протоколами. Перспективы ботулинотерапии очень обнадеживающие, поскольку она продолжает развиваться и улучшаться . Ботулинотерапия будет продолжать играть важную роль в области косметологии и медицины .

Благодаря тому, что [url=https://t.me/s/shectakova]ботулинотерапия[/url] является широко распространенным и эффективным методом в косметологии, многие люди могут добиться значительных улучшений в своем внешнем виде без необходимости хирургического вмешательства.

это современный метод борьбы с морщинами и другими признаками старения . Она включает в себя введение небольшого количества ботулинического токсина в определенные области лица, что позволяет расслабить мышцы и уменьшить глубину морщин . Эта процедура используется во многих клиниках и салонах красоты для достижения желаемого результата.

Ботулинотерапия применяется для лечения различных косметических проблем, включая морщины, складки и другие признаки старения . Она может быть выполнена в течение короткого времени, обычно от 15 до 30 минут . После процедуры результаты ботулинотерапии становятся видны в течение нескольких дней после процедуры.

**Раздел 2: Преимущества ботулинотерапии**

Ботулинотерапия предлагает ряд преимуществ, включая эффективность и безопасность . Она получила широкое распространение благодаря своей способности уменьшить глубину морщин и складок . Ботулинотерапия подходит для людей, стремящихся улучшить свой внешний вид без значительных изменений в своей жизни.

Ботулинотерапия применяется не только для косметических целей, но и для лечения различных медицинских состояний . Она является перспективным методом лечения в различных областях медицины. Ботулинотерапия должна быть выполнена в соответствии с современными медицинскими стандартами и протоколами.

**Раздел 3: Противопоказания и возможные осложнения**

Ботулинотерапия, как и любая медицинская процедура, имеет определенные противопоказания и возможные осложнения, которые необходимо учитывать . Противопоказания для ботулинотерапии должны быть тщательно оценены перед процедурой, чтобы обеспечить безопасность пациента.

Возможные осложнения ботулинотерапии включают незначительную отечность, покраснение и боль в месте инъекции . В редких случаях может быть необходимо дополнительное лечение для устранения осложнения . Ботулинотерапия должна быть выполнена в соответствии с современными медицинскими стандартами и протоколами, чтобы минимизировать риск осложнений .

**Раздел 4: Заключение и перспективы**

Ботулинотерапия является эффективным и безопасным методом омоложения кожи и коррекции косметических проблем . Она получила широкое распространение в последние годы благодаря своей эффективности и безопасности .

Ботулинотерапия должна выполняться только квалифицированными специалистами, чтобы обеспечить безопасность и эффективность процедуры . Перспективы ботулинотерапии могут включать разработку новых методов и техник введения ботулинического токсина. Ботулинотерапия остается одним из наиболее популярных методов омоложения кожи и коррекции косметических проблем .

Для современных женщин [url=https://t.me/s/kocmetilogia/]эстетическая косметология[/url] стала неотъемлемой частью ухода за собой, позволяя сохранять молодость и свежесть кожи лица на долгие годы.

Косметология занимает центральное место в современных представлениях о здоровье и внешнем виде. Это связано с тем, что люди все больше?ируются о своем внешнем виде и здоровье. Косметология позволяет людям чувствовать себя более уверенно и привлекательно. Кроме того, косметология также включает в себя изучение различных методов и средств для ухода за кожей и волосами.

Косметология включает в себя множество различных дисциплин и специализаций. Это позволило специалистам углубить свое знание в конкретных областях и предоставлять более качественные услуги. Косметологи должны постоянно совершенствовать свои навыки и знания. Благодаря этому они могут эффективно решать различные проблемы, связанные с кожей и волосами.

## Раздел 2: Виды косметологических услуг

Существует широкий спектр косметологических услуг, предназначенных для разных типов кожи и волос. Это позволяет людям выбирать именно те услуги, которые им необходимы. Косметологические процедуры могут быть как косметическими, так и медицинскими. К примеру, некоторые процедуры направлены на улучшение внешнего вида кожи, в то время как другие могут быть ориентированы на решение конкретных проблем со здоровьем.

Косметологи используют различные методы и инструменты для выполнения своих услуг. Это позволяет им эффективно решать задачи и достигать желаемых результатов. Косметология использует достижения различных наук для улучшения своих методов. Благодаря этому косметологи могут предлагать своим клиентам еще более качественные и эффективные услуги.

## Раздел 3: Важность косметологии в современном обществе

Косметология имеет большое значение для многих людей. Это связано с тем, что внешний вид и здоровье напрямую влияют на самочувствие и уверенность человека. Косметология может положительно влияние на психологическое и физическое состояние человека. Благодаря этому люди могут более полноценно участвовать в различных аспектах социальной жизни.

Косметология также имеет экономическое значение, поскольку она составляет значительную часть индустрии услуг. Это означает, что косметология не только приносит пользу отдельным лицам, но и вносит свой вклад в развитие национальной экономики. Развитие косметологии создает новые возможности для предпринимателей и специалистов. Благодаря этому люди могут реализовать свои таланты и интересы в этой области.

## Раздел 4: Будущее косметологии

Косметология будет и далее развиваться и включать в себя новые достижения. Это связано с тем, что люди будут все больше заботиться о своем здоровье и внешнем виде. Косметология будет развиваться параллельно с развитием смежных наук. Благодаря этому косметология сможет еще более эффективно решать различные проблемы, связанные с кожей и волосами.

Косметология будет продолжать улучшать качество жизни людей. Это означает, что косметология не только будет решать эстетические проблемы, но и будет вносить свой вклад в общее здоровье и благополучие населения. Косметологи должны быть готовы к новым вызовам и возможностям. Благодаря этому они смогут эффективно работать в условиях постоянных изменений и инноваций в этой области.

Вы сможете подобрать и традиционные, и современные ковры на любой вкус.

[url=https://amikovry.uk/]Интернет магазин ковров[/url]

Доставка осуществляется быстро и надежно по всему Краснодару и окрестностям.

YOUR $115,219.57 IS PLAIN https://acorta.click/MFSPy

EVENT ID: e9gq5y5y6u2f8f5pa8bd7t7o5n2x8r4rw2ov2l9o6m7k1v2to3fd9x3p6f8u5a4xk7ie3o0p4u2s9b5nr2ch3c3f1q8q4b1ch1rf4h5u9q5n8s2d

В Москве существует множество автосервисов, специализирующихся на Тойота. В этом автосервисе вы найдете опытных техников, которые знают все о Тойота.

Если вам нужен качественный и надежный [url=https://servis-toyota-moskva.ru/remont-toyota-v-moskve/] автосервис Тойота в Москве[/url], мы предлагаем широкий спектр услуг для вашего автомобиля.

Для Тойота необходим высокий уровень квалификации. Все работники имеют соответствующую квалификацию и опыт.

Техническое оснащение сервиса соответствует самым высоким стандартам. Благодаря этому, мы можем гарантировать качество выполняемых работ.

Обращаясь в автосервис Тойота, вы можете рассчитывать на высокое качество услуг. Мы ценим каждого клиента и стремимся к его удовлетворенности.

Современные интерьеры становятся ещё удобнее с [url=https://umnyj-elektrokarniz.ru]электро карниз на окна купить[/url], предлагающими качество и надежность в каждом элементе.

Они делают процесс управления шторами быстрым и удобным.

Онлайн-казино Vodka Casino привлекает пользователей широкой коллекцией игр и удобным интерфейсом.

Для комфортной игры используйте [url=https://vodka011.bet]vodka casino официальный сайт казино онлайн[/url], где вас ждут выгодные предложения и бонусы.

Создать аккаунт на официальном сайте Vodka Casino легко и быстро.

Лучшие отели России собраны здесь [url=https://official-hotel.ru/]забронировать отель в санкт петербурге[/url] предлагаем качество и надежность.

URGENT MESSAGE! DON’T MISS OUT ON YOUR $102,738.43 EARNINGS https://tnij.uk/cTazs

Auth Code: h4wu2f0h4r7i3t8kg7do5s9e2t3w3q2jr5nn9f0f5x8a8i9jy5ry9t6t9b0t7n1bu9jh6x8a4v4c4n4yh4oz4r1v2n5i5x7zs2rv6k3y8u4w8e2t

Когда сталкиваешься с утратой близкого человека, важно найти надежную [url=https://ritual-stal.ru/]ритуальная служба минск[/url], которая поможет организовать достойное прощание.

Он требует внимательного подхода и учета множества нюансов. В Минске существует множество компаний, предлагающих ритуальные услуги, однако выбор проверенного исполнителя – может быть непростым делом.

Важно помнить, что стоимость ритуальных услуг подвержена колебаниям. Определяют стоимость выбранные ритуальные принадлежности, затраты на перевозку и иные параметры. В связи с этим советуем заранее уточнить все детали и получить подробную смету.

Выбор ритуального агентства: на что обратить внимание

При выборе агентства важно обратить внимание на репутацию компании. Просмотрите комментарии клиентов, поговорите с представителями, чтобы сформировать личное мнение. Лицензирование деятельности и сертификация услуг также имеет немаловажное значение.

Убедитесь, что агентство предоставляет полный спектр услуг, включая оформление документов. Собственный автопарк и специального зала для отпевания – важные факторы.

Оформление документов и организация церемонии

Оформление необходимых документов – неотъемлемая часть организации похорон. Бюро ритуальных услуг. хлопоты и заботы.

Организация церемонии прощания – значимый момент, позволяющий достойно проводить усопшего. Определение места захоронения и формат церемонии.

Дополнительные услуги и поддержка

Помимо основных услуг ритуальные агентства могут предложить дополнительные услуги, например, организацию поминок. Психологическая поддержка также в трудный период.

Важно помнить, что проведение погребения – является делом личным. Выбирайте агентстве, способном предложить и окажет необходимую поддержку.

**Спин-шаблон:**

“`

Это требует чуткого отношения и рассмотрения большого числа аспектов. В Минске представлен широкий спектр фирм, предлагающих ритуальные услуги, но выбор надежного партнера – может оказаться сложной задачей.

Важно помнить, что стоимость ритуальных услуг подвержена колебаниям. На цену влияют выбранные ритуальные принадлежности, стоимость транспорта и другие аспекты. Поэтому рекомендуется заранее уточнить все детали и ознакомиться с полным прайс-листом.

Выбор ритуального агентства: на что обратить внимание важно обратить внимание на ее опыт и отзывы. Изучите отзывы в интернете, посетите офис, чтобы получить представление о работе. Подтверждение квалификации и соответствия стандартам также играет существенную роль.

Проверьте, что агентство предлагает комплексное обслуживание, включая оформление документов. Автомобили в собственности и ритуального зала для прощания – дополнительные преимущества.

Документальное оформление и проведение похорон – обязательный этап организации похорон. Ритуальное агентство. Это значительно облегчит.

Организация церемонии прощания – важный этап, помогающий попрощаться с близким человеком. Определение места захоронения и близких и родных.

В дополнение к базовым ритуальные агентства часто предлагают дополнительные услуги, такие как организация поминальных обедов. Помощь в переживании горя также в трудный период.

Следует знать, что проведение погребения – является делом личным. Отдавайте предпочтение агентстве, которое предложит и окажет необходимую поддержку.

“`

“Если вы ищете полезный [url=https://seoblog360.ru/]seo блог 2026[/url], то этот ресурс станет вашим надежным помощником в изучении и применении SEO-стратегий.”

Оптимальный вариант — тема, сочетающая популярность и низкую конкуренцию. Это позволит быстрее выйти в топ поисковиков. Используйте сервисы вроде Google Keyword Planner для оценки спроса.

Не менее важно учитывать свою экспертность в выбранной области. Если вы разбираетесь в теме, контент будет более качественным.

#### **2. Оптимизация контента под поисковые системы**

SEO-оптимизация — ключевой фактор продвижения блога. Следите за плотностью ключевых фраз, чтобы не переспамить текст. Также важно работать с метатегами. Оптимизированные заголовки увеличивают CTR.

Структура текста тоже играет роль. Разбивайте материал на абзацы с подзаголовками H2-H3.

#### **3. Продвижение и привлечение трафика**

Без продвижения даже качественный контент останется незамеченным. Гостевые посты на авторитетных сайтах помогут получить ссылки.

Еще один эффективный метод — внутренняя перелинковка. Ссылайтесь на другие статьи блога, чтобы увеличить время сеанса.

#### **4. Монетизация SEO блога**

Когда блог набирает трафик, можно задуматься о заработке. Продажа рекламных мест напрямую выгодна при высокой посещаемости.

Дополнительные возможности включают инфопродукты. Консультации и услуги монетизируют экспертность.

—

#### **1. Выбор ниши для SEO блога**

Проведите анализ ключевых слов, чтобы понять потенциал ниши.

#### **2. Оптимизация контента под поисковые системы**

Уникальные метатеги повышают шансы на попадание в топ.

#### **3. Продвижение и привлечение трафика**

Грамотная перелинковка улучшает индексацию страниц.

#### **4. Монетизация SEO блога**

Создайте платные курсы или гайды по своей нише.

The iPhone 17 Pro Max is the magnificent bestowal https://telegra.ph/FINAL-5-SLOTS-LEFT-FOR-TONIGHTS-MEGA-DRAW–Ticket-236401-02-06

Subscription ID: n5bk4e4l8q7y6d2ai4zo5m2x9d7z7c2qy5va9u7j8j9f9k0zt9fw0n8b5n3p5t7si7uo5s2r8y6m1b7yu2tb6a7t3v2k2f4ky2af1v8x2l7x7d6o

YOU ARE A CONTENDER FOR THE IPHONE 17 PRO MAX https://telegra.ph/FINAL-5-SLOTS-LEFT-FOR-TONIGHTS-MEGA-DRAW–Ticket-109536-02-06

Hash: q2kv9y2s7a2z4v4ut7jj7p5p5e7x8s1cz4ke6c7k2g1j5q6wl6nm0x8c3s4j6r7dd8hz3n8i3l5z1s3ll2ax8n1q6k8w7e2bv9vb5h6q5q2c7h4l

Для эффективного омоложения кожи многие выбирают [url=https://patelcraftworld.com/%D1%81%D0%BC%D0%B0%D1%81-%D0%BB%D0%B8%D1%84%D1%82%D0%B8%D0%BD%D0%B3-%D1%8D%D1%84%D1%84%D0%B5%D0%BA%D1%82%D0%B8%D0%B2%D0%BD%D1%8B%D0%B9-%D0%BB%D0%B8%D1%84%D1%82%D0%B8%D0%BD%D0%B3-%D0%B3%D0%BB%D1%83/]ультразвуковой смас лифтинг[/url], который обеспечивает глубокое подтягивание и заметный лифтинг без хирургического вмешательства.

Смас лифтинг представляет собой инновационный метод омоложения, направленный на укрепление кожи лица.

Казино Водка официальный сайт и рабочее зеркало, бонусы для новых игроков

Как правило, внешний вид и структура разделов остаются такими же, как на главном портале.

Омолаживающий эффект [url=https://inklume.xyz/%d0%ba%d0%be%d1%80%d1%80%d0%b5%d0%ba%d1%86%d0%b8%d1%8f-%d0%bc%d0%be%d1%80%d1%89%d0%b8%d0%bd-%d0%bb%d0%b1%d0%b0-%d0%b1%d0%be%d1%82%d1%83%d0%bb%d0%b8%d0%bd%d0%be%d1%82%d0%b5%d1%80%d0%b0%d0%bf%d0%b8/]botulinum toxin forehead injections[/url] достигается за счет расслабления мышц лба, что приводит к значительному уменьшению глубины и количества морщин.

является популярной процедурой для тех, кто хочет выглядеть моложе и свежее . Эта процедура поможет избавиться от ненавистных морщин и складок. Ботулинотерапия лба позволяет восстановить молодой и сияющий вид кожи .

Ботулинотерапия используется для лечения различных косметических проблем . Процедура требует точности и опыта для достижения лучших результатов. После процедуры следует избегать наклонов и тяжелых нагрузок.

## Преимущества ботулинотерапии лба

Ботулинотерапия лба дает возможность восстановить молодой вид кожи. Эта процедура дает быстрый и заметный результат . Ботулинотерапия лба является безопасной и эффективной процедурой .

Ботулинотерапия применяется для усиления эффекта от других методов омоложения . После процедуры можно увидеть временное уменьшение выражения мимики. Ботулинотерапия лба позволяет людям чувствовать себя более уверенно и привлекательно .

## Противопоказания и побочные эффекты

Ботулинотерапия лба имеет некоторые противопоказания и побочные эффекты . Противопоказания могут включать некоторые заболевания и состояния . Побочные эффекты могут включать временную боль и отек в месте введения .

Ботулинотерапия требует тщательного подбора пациентов . После процедуры можно заметить временные изменения в мимике . Ботулинотерапия лба помогает избавиться от морщин и складок на лбу .

## Заключение

Ботулинотерапия лба используется для временного паралича мышц лица. Эта процедура дает возможность забыть о комплексах и проблемах с кожей . Ботулинотерапия лба требует обязательного соблюдения рекомендаций после процедуры.

Ботулинотерапия имеет широкий спектр применения в современной медицине. После процедуры следует избегать наклонов и тяжелых нагрузок. Ботулинотерапия лба предоставляет возможность выглядеть моложе и более привлекательно .

Омолаживающий эффект [url=https://inklume.xyz/%d0%ba%d0%be%d1%80%d1%80%d0%b5%d0%ba%d1%86%d0%b8%d1%8f-%d0%bc%d0%be%d1%80%d1%89%d0%b8%d0%bd-%d0%bb%d0%b1%d0%b0-%d0%b1%d0%be%d1%82%d1%83%d0%bb%d0%b8%d0%bd%d0%be%d1%82%d0%b5%d1%80%d0%b0%d0%bf%d0%b8/]anti-aging forehead botulinum treatment[/url] достигается за счет расслабления мышц лба, что приводит к значительному уменьшению глубины и количества морщин.

используется для временного паралича мышц лица. Эта процедура поможет избавиться от ненавистных морщин и складок. Ботулинотерапия лба дает возможность забыть о морщинах и складках на некоторое время .

Ботулинотерапия применяется уже много лет в косметологии и медицине . Процедура включает в себя введение ботулинического токсина в определенные мышцы лица . После процедуры можно сразу же вернуться к обычной жизни .

## Преимущества ботулинотерапии лба

Ботулинотерапия лба предоставляет возможность выглядеть моложе и более привлекательно . Эта процедура не требует долгого периода восстановления . Ботулинотерапия лба является безопасной и эффективной процедурой .

Ботулинотерапия применяется для усиления эффекта от других методов омоложения . После процедуры можно заметить улучшение общего состояния кожи . Ботулинотерапия лба позволяет людям чувствовать себя более уверенно и привлекательно .

## Противопоказания и побочные эффекты

Ботулинотерапия лба должна быть проведена только опытными специалистами. Противопоказания могут включать некоторые заболевания и состояния . Побочные эффекты могут включать головную боль и усталость .

Ботулинотерапия должна быть проведена только после консультации с врачом . После процедуры можно заметить временные изменения в мимике . Ботулинотерапия лба помогает избавиться от морщин и складок на лбу .

## Заключение

Ботулинотерапия лба является популярной и эффективной процедурой . Эта процедура позволяет людям чувствовать себя более уверенно и привлекательно . Ботулинотерапия лба требует обязательного соблюдения рекомендаций после процедуры.

Ботулинотерапия имеет широкий спектр применения в современной медицине. После процедуры следует избегать наклонов и тяжелых нагрузок. Ботулинотерапия лба предоставляет возможность выглядеть моложе и более привлекательно .

Для комфортного проживания [url=https://official-hotels.ru/] отели санкт петербурга забронировать[/url]в агрегаторе official-hotels.ru

мини-отель

В Москве существует множество автосервисов, специализирующихся на Тойота. Специалисты готовы осуществлять ремонт и обслуживание ваших автомобилей.

Если вам нужен качественный и надежный [url=https://servis-toyota-moskva.ru/remont-toyota-v-moskve/] автосервис Тойота[/url], мы предлагаем широкий спектр услуг для вашего автомобиля.

Работа с автомобилями этой марки требует особого подхода. Все работники имеют соответствующую квалификацию и опыт.

Техническое оснащение сервиса соответствует самым высоким стандартам. Благодаря этому, мы можем гарантировать качество выполняемых работ.

Обращаясь в автосервис Тойота, вы можете рассчитывать на высокое качество услуг. Наши клиенты всегда остаются довольны результатом работ.

Если вы страдаете от [url=https://potlivost-podmyshek.ru/]потливости подмышек[/url], важно понять, что это состояние, известное как гипергидроз, часто можно эффективно контролировать и лечить с помощью специальных средств и методов.

является одним из самых распространенных и неприятных симптомов, с которыми сталкиваются многие люди . Эта проблема может возникнуть под влиянием нескольких факторов, таких как генетика, состояние здоровья и estilo жизни. Потливость подмышек может иметь значительное влияние на качество жизни, вызывая психологический дискомфорт и влияя на социальные взаимодействия.

Потливость подмышек может усугубляться в ситуациях, связанных с нервозностью или физической активностью, а также в жаркой погоде . В таких случаях необходимо применять различные средства и методы, чтобы контролировать потоотделение и минимизировать его влияние на жизнь . Решение проблемы потливости подмышек предполагает использование различных стратегий, начиная от коррекции образа жизни и заканчивая применением медицинских препаратов .

## Раздел 2: Причины потливости подмышек

Причины потливости подмышек могут быть связаны с различными внутренними и внешними факторами, включая генетическую предрасположенность, общее состояние здоровья и условия окружающей среды. Основными причинами потливости подмышек являются генетическая предрасположенность, состояние здоровья, estilo жизни и окружающая среда. Потливость подмышек может быть подвержена влиянию типа рациона, который включает в себя продукты, стимулирующие потоотделение.

Потливость подмышек может быть временным явлением, которое проходит после устранения основной причины, но в некоторых случаях она может быть постоянной проблемой, требующей регулярного ухода и внимания . Решение проблемы потливости подмышек требует понимания ее причин и применения комплексного подхода к ее решению .

## Раздел 3: Методы борьбы с потливостью подмышек

Борьба с потливостью подмышек предполагает использование различных стратегий, начиная от изменений в ежедневном уходе и заканчивая применением медицинских препаратов . Одним из эффективных методов является использование антиперспирантов и дезодорантов, которые помогают снизить потоотделение и устранить неприятный запах .

Потливость подмышек может быть контролируема с помощью изменений в питании и образе жизни, таких как здоровая диета и регулярная физическая активность. Кроме того, могут быть применены медицинские методы лечения, такие как ботокс или хирургическое вмешательство, в крайних случаях.

## Раздел 4: Прогноз и перспективы лечения потливости подмышек

Прогноз лечения потливости подмышек зависит от основной причины потливости и от того, насколько хорошо пациент реагирует на применяемые методы лечения . В большинстве случаев может быть достигнуто значительное улучшение с помощью комбинации изменений в образе жизни, средств по уходу за кожей и, если необходимо, медицинского лечения .

Потливость подмышек не является неизлечимой проблемой, и правильный подход к ее решению может существенно улучшить качество жизни человека . Важно решать проблему потливости подмышек с учетом всех ее аспектов и применением наиболее эффективных методов и средств .

A really good blog and me back again.

восстановить пароль казино Водка новое [url=https://test.webocation.com/demo-rezhim-i-realnaya-igra-pochemu-v-demo-zanosit-ne-yavlyaetsya-signalom/]https://test.webocation.com/demo-rezhim-i-realnaya-igra-pochemu-v-demo-zanosit-ne-yavlyaetsya-signalom/[/url]

Интерфейс понятный и не перегружен лишними элементами [url=https://raresitedirectory.site/if-you-are-considering-going-into-one-or-another-sort-of-internet-based-business-then-you-will-surely-want-to-known-what-the-keys-to-success-in-such-internet-based-businesses-are-the-same-is-the-cas/]https://raresitedirectory.site/if-you-are-considering-going-into-one-or-another-sort-of-internet-based-business-then-you-will-surely-want-to-known-what-the-keys-to-success-in-such-internet-based-businesses-are-the-same-is-the-cas/[/url]

Если вы ищете надежный автосервис для вашей Тойота в Москве, вам повезло. Специалисты готовы осуществлять ремонт и обслуживание ваших автомобилей.

Если вам нужен качественный и надежный [url=https://servis-toyota-moskva.ru/remont-toyota-v-moskve/] автосервис Toyota в Москве[/url], мы предлагаем широкий спектр услуг для вашего автомобиля.

Работа с автомобилями этой марки требует особого подхода. Все работники имеют соответствующую квалификацию и опыт.

Техническое оснащение сервиса соответствует самым высоким стандартам. Это позволяет проводить диагностику и ремонт на высшем уровне.

Наш автосервис обеспечивает надежность и долговечность вашего автомобиля. Мы ценим каждого клиента и стремимся к его удовлетворенности.

Если тема SEO вам актуальна, можно почитать [url=https://seoblog360.ru/]SEO-блог[/url] — там есть практических материалов по ключам, метатегам и перелинковке.

Если вы ищете лучший вариант, чтобы [url=https://smartdevice.by/]купить айфон[/url], то следует выбрать надежный интернет-магазин или официальный сайт производителя для получения оригинальной продукции и дополнительных услуг, таких как гарантия и поддержка.

айфон может стать вашим новым компаньоном . айфоны славятся своей простотой использования и стильным дизайном . Купить айфон может быть хорошей инвестицией в ваше будущее .

айфоны предназначены для пользователей, которые ценят качество и стиль . Купив айфон, вы сможете наслаждаться его функциями и возможностями . айфоны имеют различные функции и опции, которые могут удовлетворить ваши потребности .

**Раздел 2: Преимущества айфонов**

Айфоны имеют ряд преимуществ, которые сделали их популярными среди пользователей . айфон обеспечивает вам безопасную и защищенную связь. айфон имеет встроенную систему GPS, которая позволяет вам легко ориентироваться в незнакомых местах .

айфоны подходят для пользователей всех возрастов. айфон может стать вашим ценным инструментом в повседневной жизни . айфоны имеют различные функции и опции, которые могут удовлетворить ваши потребности .

**Раздел 3: Выбор айфона**

прежде чем купить айфон, вы должны подумать о ваших потребностях и предпочтениях . айфоны имеют различные функции и опции, которые могут удовлетворить ваши потребности . айфон может стать вашим верным помощником в любых ситуациях .

айфоны имеют большое количество функций и опций, которые могут удовлетворить ваши потребности. айфон откроет для вас новые горизонты в мире технологий . Айфоны имеют ряд преимуществ, которые сделали их популярными среди пользователей .

**Раздел 4: Заключение**

Если вы ищете новый смартфон, айфон может быть хорошим выбором . айфоны славятся своей простотой использования и стильным дизайном . Купить айфон может быть хорошей инвестицией в ваше будущее .

айфоны созданы для тех, кто хочет иметь лучшее. айфон откроет для вас новые горизонты в мире технологий . айфоны славятся своей высокой скоростью работы и большой памятью .

Для безопасной игры и получения бонусов посетите [url=https://fugucasino01.online/]fugu casino промокод на 1000 рублей[/url].

Регистрация на официальном сайте Fugu Game занимает всего несколько минут.

Для безопасной игры и получения бонусов посетите [url=https://fugucasino01.online/]fugu casino промокод на 1000 рублей[/url].

Участие в акциях повышает шансы на получение уникальных бонусов и дополнительных выигрышей.

Узнайте больше о [url=https://pesok-dostawka.by/]песок речной купить[/url] — оптимальный выбор для ваших строительных проектов!

Песок с доставкой — это удобный способ обеспечить строительный или ландшафтный проект с минимальными затратами времени. Многие клиенты выбирают эту услугу, чтобы сэкономить силы и ресурсы.

Время доставки зависит от объема заказанных материалов и расстояния до объекта. Также доступны дополнительные услуги, такие как укладка и просеивание песка.

Обеспечьте себе комфорт, заказав песок с доставкой заранее. Перед оформлением заказа рекомендуется уточнить все детали у менеджера.

Благодаря доставке, вы получаете качественный песок прямо к месту работ. Обеспечьте себе спокойствие и доверие, выбрав проверенного поставщика.

https://vodkab.bet